Your partner for high efficiency in aeration technology & biofilm processes

We are your reliable partner for innovative solutions in the field of aeration technology and biofilm technology. Our many years of experience and expertise enable us to develop customized and efficient solutions for your requirements which we provide in close cooperation with our partners.

Our product range includes innovative, high efficient aeration systems that ensure optimum oxygen input and high-quality growth media that significantly increases the capacity of the process. In addition, we offer the ShearCon process, which is based on the combination of our areas of expertise.

We also ensure that all products are state of the art through continuous research and development. The products can be manufactured to meet BABA requirements and be Made in the USA. Special emphasis is placed on sustainability and environmental friendliness in order to minimize environmental impact and contribute to global environmental improvement.

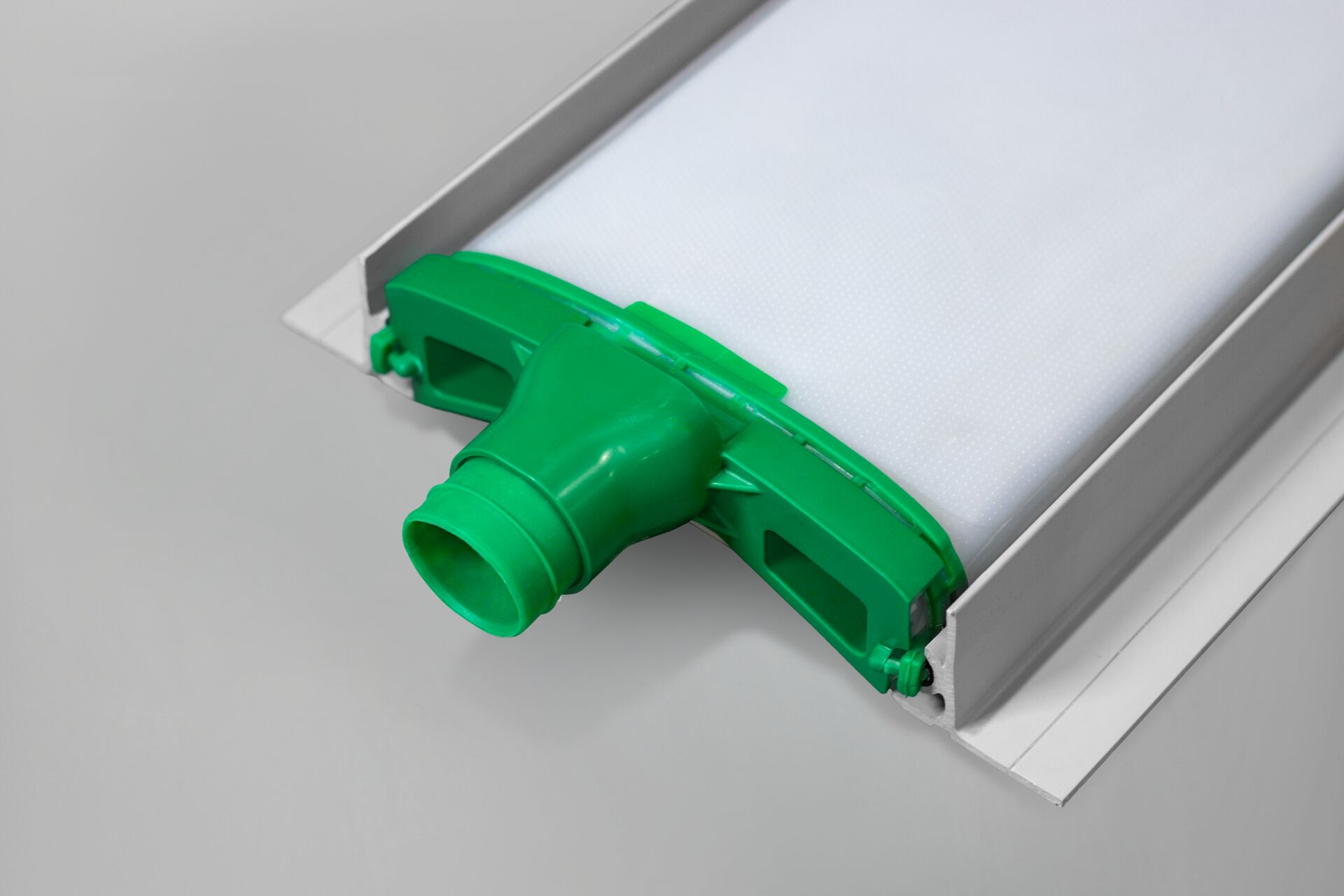

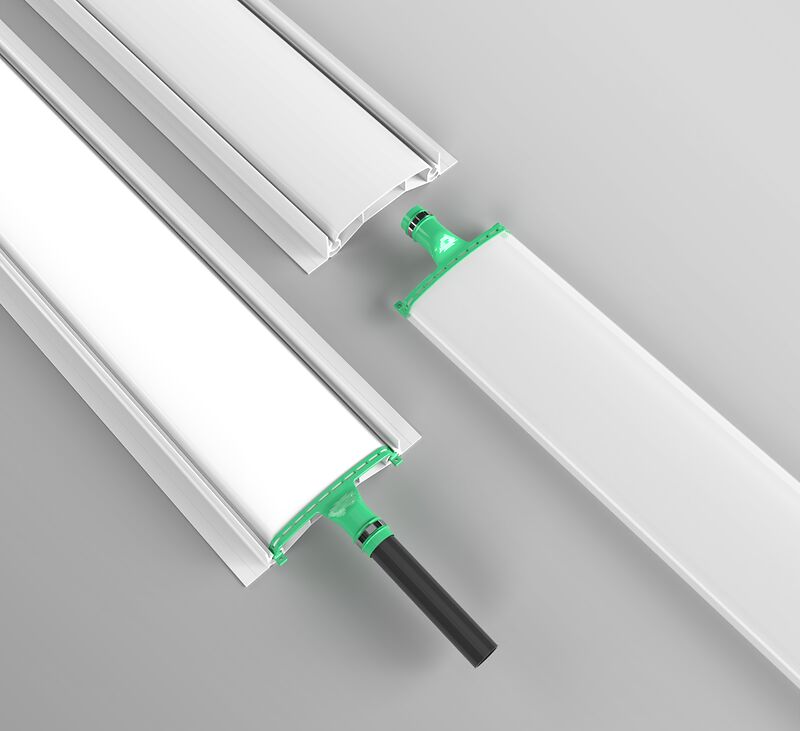

The Smart Strip Diffuser

It is inevitable that every diffuser, regardless of its quality, will eventually reach the end of its service life and require a replacement. The latest this replacement should be done is when the membranes fail mechanically. In the past, the entire diffuser was always removed from the tank when it came to plate and strip diffusers. Replacing the membrane was either not doable with plate and strip diffusers or only possible with a significant amount of time and effort. A solution to this problem has now been developed.

| Type | strip diffuser |

| Material | polyurethane, regranulated PVC |

| Length | 1,5m, 2m, 2,5m, 3m, 3,5m, 4m |

| Area of application | industrial and municipal wastewater |

Type: strip diffuser

Material: polyurethane, regranulated PVC

Length: 1.5m, 2m, 2.5m, 3m, 3.5m, 4m

Area of application: industrial and municipal wastewater

Wastewater Treatment

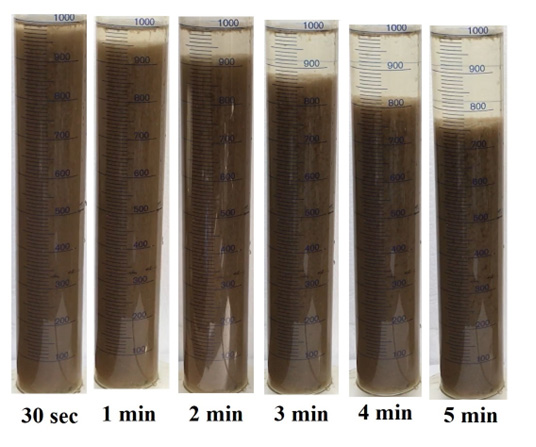

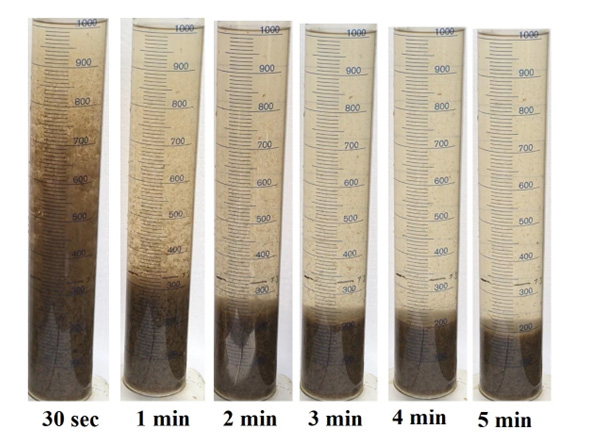

Conventional wastewater treatment plants (WWTPs) are limited by two main factors in terms of biomass concentrations in the aeration tank: the settling velocity of sludge and the sedimentation volume within the secondary clarifier. The IFAS system and the ShearCon process provide a solution to this issue, enabling a significantly higher concentration of MLSS and a higher sludge age than what is achievable in conventional WWTPs.

The ShearCon process represents an enhancement of the usual IFAS process. It enriches high-quality biomass in the biological reactor through the use of CLERATEC® technology and a high efficient aeration system. The premium sludge produced by the ShearCon process is distinguished by two unique characteristics: an excellent settling velocity and a notably high nitrification rate as shown by data beside.

| Parameters | Inlet [mg/l] | Outflow [mg/l] | Removal rate [%] |

| CSB | 321 | 53 | 82,9 |

| BSB5 | 172 | 11 | 93,5 |

| NH4-N | 36 | 32 | 11,1 |

Inlet

CSB: 321 mg/l

BSB4: 172 mg/l

NH4-N: 36 mg/l

Outflow

CSB: 53 mg/l

BSB4: 11 mg/l

NH4-N: 32 mg/l

Removal rate

CSB: 82,9 %

BSB4: 93,5 %

NH4-N: 11,1 %

| Parameters | Inlet [mg/l] | Outflow [mg/l] | Removal rate [%] | Limit value [mg/l] |

| CSB | 602 | 19 | 96,8 | 33 |

| BSB5 | 213 | 1,3 | 99,4 | 15 |

| NH4-N (Jan-Dec) | 40 | 1,17 | 97,1 | - |

| NH4-N (May-Oct) | 40 | 0,3 | 99,3 | 10 |

Inlet

CSB: 602 mg/l

BSB4: 213 mg/l

NH4-N: 40 mg/l

Outflow

CSB: 19 mg/l

BSB4: 1,3 mg/l

NH4-N: 1,17 mg/l (Jan-Dez)

NH4-N: 0,3 mg/l (Mai-Okt)

Removal rate

CSB: 96,8 %

BSB4: 99,4 %

NH4-N: 97,1 % (Jan-Dez)

NH4-N: 99,3 % (Mai-Okt)

Limit value

CSB: 33 mg/l

BSB4: 15 mg/l

NH4-N: 10 mg/l